8 Marine View, #39-04, Asia Square Tower 1, Singapore-018960

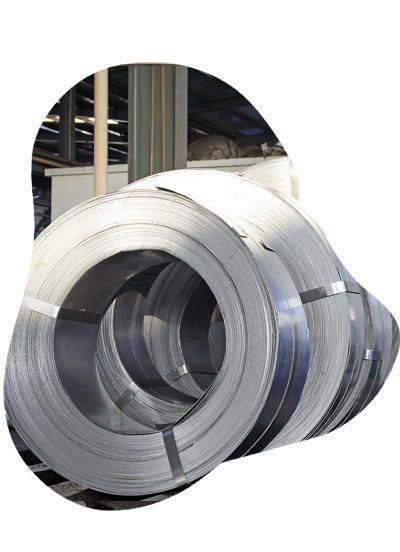

Endless casting & rolling

Endless casting & rolling

Direct linked casting and rolling plants

-

A new generation of future-oriented casting-rolling complexes.

The direct linking of casting and rolling processes is an essential factor to minimize energy consumption in rolling, improve product consistency, and maximize yield. Traders of Pacific has direct linked casting and rolling solutions for both flat and long products.

Arvedi esp — real endless strip production

-

The trailblazing endless strip production technology offers the promise of revolutionizing flat-steel production in the same way that LD converter steelmaking technology and continuous casting changed the face of the steelmaking industry in the previous century. A wide range of high-quality and ultra-thin steel grades can be produced with the endless cast-rolling process

The Arvedi ESP process produces hot strip in a combined, continuous and uninterrupted casting and rolling process. In this type of plant, the energy consumption and the associated costs are up to 45 percent lower than those of conventional casting and rolling processes. This also means a significant reduction of CO2 emissions. With a length of just 180 meters, the plants also have considerably more compact dimensions than conventional casting and rolling mills. A wide range of high-quality and ultra-thin steel grades can be produced with the endless cast-rolling process.

Winlink — the direct rolling of bars

-

Reducing the total final product cost. High-level technological solutions are combined in a unique compact installation. A small size plant can become competitive against the traditional larger Mini Mills.

Addressed to product-cost based markets, WinLink reduces the requirements of both the capital and operation expenditures. A reduction of the total final product cost is provided through high-level technological solutions in compact installation. A micro-size smart plant has become more than competitive to the traditional larger Mini Mills. WinLink is the innovative technology for endless or semi-endless production of long products from liquid steel without interruption. A high-speed caster is directly linked to a high-availability rolling mill, where the conventional billet furnace is replaced by an advanced induction unit, resulting in a compact and energy efficient production line. WinLink enables low investment expenditures, reduced transformation costs, significant energy savings, higher yield, smaller land requirements and reduced emissions of carbon dioxide. It represents the excellent solution to replace existing lines or to enter into new market areas.

00

+Professional team

00

kSatisfied customers

00

%Our success rate